Home » Sodium Bicarbonate Powder

What Is Sodium Bicarbonate Powder

- Other names: Sodium Hydrogen Carbonate, Baking Soda, Bicarbonate of Soda

- Chemical Formula: NaHCO3

- Grade: Industrial grade, food grade

- Appearance: White crystalline powder

- Content of NaHCO3: ≥99.0- 100.5%

- Cas No.:144-55-8

- HS Code: 28363000

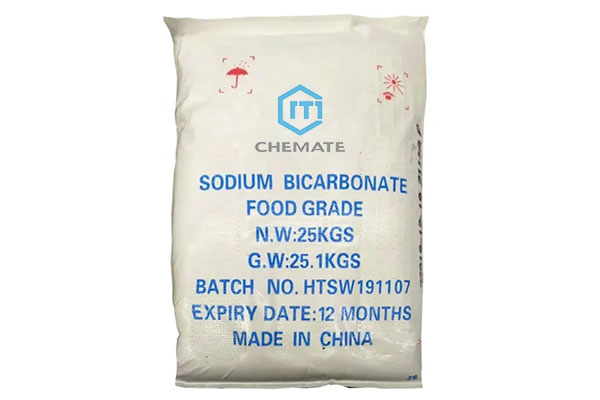

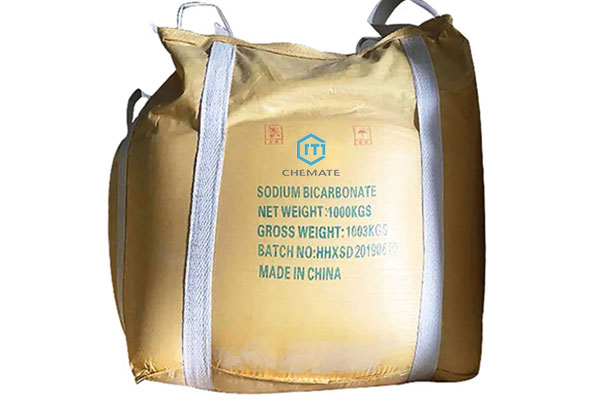

- Package: 25kg, 1000kg

- Applications: Sodium Bicarbonate powder is Mainly applied as food additive in food stuff industry, feed additives for animals, foaming agent in rubber industry, acidifying agent in medicine industry, compounding ingredient in detergent making, detergent in movie making, Carbon Dioxide(CO2) reactor in beer,drinks,etc.

Technical Specifications of sodium Bicarbonate For Sale in Chemate

| Classification | Items | Standards | Result |

| Food grade | Content as NaHCO3% | 99-100.5 % | 99.52 |

| Heavy Metal as Pb% | ≤0.0005 | <0.0005 | |

| Arsenic as As% | ≤0.0001 | ≤0.0001 | |

| Loss on drying% | ≤0.20 | 0.03 | |

| Ph value | ≤8.5 | 8.29 | |

| Chloride(CL)% | ≤0.40 | <0.20 | |

| Industrial grade | Total Alkali(Quality Fraction of NaHCO3 Dry Basis)% | ≥99.5 | ≥100.01 |

| Lost of Ignition% | ≤0.1 | ≤0.06 | |

| PH 90(10g /L ) | ≤8.3 | ≤8.23 | |

| Cl (Quality Fraction of Cl Dry Basis) % | ≤0.10 | ≤0.09 | |

| Fe Quality Fraction (Dry Basis) % | ≤0.001 | ≤0.0006 | |

| Sulfate (Qality Fraction of SO4 Dry Basis)% | ≤0.02 | ≤0.007 | |

| Water insoluble matter % | ≤0.01 | ≤0.006 | |

| As Quality Fraction(Dry Basis)% | ≤0.0001 | <0.0001 | |

| Pb Quality Fraction(Dry Basis)% | ≤0.0005 | <0.0005 |

What Are Types of Sodium Bicarbonate for Sale in Chemate

As sodium bicarbonate bulk supplier, Chemate can supply industrial grade sodium bicarbonate, food grade sodium bicarbonate, as well as feed grade sodium bicarbonate. They have slight difference in product purity and impurity content, so the prices are also different. In addition, the prices of raw materials used to produce sodium bicarbonate powder are also changing. Feel free to inquiry us for the latest sodium bicarbonate price.

Would Like The Quotation

Leave more about your requirements, such as, tech grade or food grade, quantity, package, country, etc.

What Is Sodium Bicarbonate Powder Used For

- In fire fighting equipment, sodium bicarbonate can be used to produce acid-base fire extinguishers and foam fire extinguishers.

- In the rubber industry, itcan be used in the production of rubber and sponge. Cooperate with edible alkali and pore forming agent to achieve the effect of uniform pore opening.

- In the metallurgical industry, sodium bicarbonate powder can be used as a flux for casting steel ingots.

- In the machinery industry, itcan be used as a forming modifier for sand molds of steel castings.

- In the printing and dyeing industry, sodium bicarbonate can be used as a color-fixing agent for dyeing and printing, an acid-base buffer, and a post-treatment agent for fabric dyeing and finishing. Adding baking soda in the dyeing can prevent the bobbin from producing colored flowers, and it can also be used as a detergent for wool.

- In food processing, sodium bicarbonate baking soda powder is the most widely used loosening agent, used in the production of biscuits, snacks, steamed buns, bread, etc.

- It is a generator of carbon dioxide in carbonated beverages. Used together with sodium citrate and tartaric acid to prepare foaming gel for solid refreshing drinks.

- It can be compounded with alum to make alkaline fermentation powder, and can also be compounded with soda ash to make civil stone soda.

- Used as a butter preservative.

- Because it is harmless and weakly alkaline, it can be used as a color protectant for fruits and vegetables in vegetable processing.When washing fruits and vegetables, adding about 0.1%~0.2% sodium bicarbonate powder can stabilize the green color.

- Because it can increase the PH value, it can increase the water solubility of protein, promote the softening of food tissue cells, and remove the bitterness.

- It has the effect of removing mutton in milk, and the dosage is 0.001%~0.002%.

- Bicarbonate of Soda can be used as a pharmaceutical raw material to treat hyperacidity, metabolic acidosis, and alkalize urine to prevent uric acid kidney stones.

- It can reduce the nephrotoxicity of sulfonamides and prevent hemoglobin deposition in the renal tubules during acute hemolysis.

- Intravenous infusion has a non-specific therapeutic effect on drug poisoning such as barbiturates, salicylates and methanol.

- Using sodium bicarbonate powder as feed additive for poultry can effectively improve the feed digestibility, utilization rate and energy conversion rate of poultry.

- Accelerate the absorption and utilization of nutrients and the excretion of harmful substances.

- It has significant effects on improving the anti-stress ability of poultry, promoting growth, increasing egg production, and improving eggshell quality.

- Improve the animal’s resistance to heat stress.

- Mediation of the body’s acid-base balance.

- Prevent diseases and reduce the toxic and side effects of drugs.

- Used as an analytical reagent and used in inorganic synthesis.

- It can be used to prepare sodium carbonate-sodium bicarbonate buffer solution. When adding a small amount of acid or alkali, it can keep the concentration of hydrogen ions from changing significantly, and keep the pH value of the system relatively stable.

More About Sodium Bicarbonate Powder

The production process of baking soda can be divided into two parts, sodium carbonate solution preparation, carbonation and other processes.

Preparation of sodium carbonate solution

Sodium carbonate solution for the production of baking soda powder can usually be used in four ways, light soda ash dissolution, trona dissolution, heavy alkali wet decomposition and furnace gas alkali powder recovery.

Using light soda ash as raw material, recycle light soda ash or defective alkali and sweeping ash to soda ash, add it to the soda tank.

Add baking soda filtrate and supplementary condensate to dissolve, and heat with indirect steam under stirring.

In order to remove impurities such as iron content, sodium sulfide is usually added.

Carbonation and other processes

First, before carbonation, it enters the clarification tank for clarification to remove insoluble impurities. Send the clarified liquid to a filter to remove finer impurities.

After filtering, the lye is pumped into the upper part of the carbonation tower. Then it contact with the CO2 gas fed from the bottom from top to bottom to carry out carbonation reaction and generate sodium bicarbonate crystals.

The lye absorbs CO2 to react to generate sodium bicarbonate and release heat to heat the solution itself, which is beneficial to accelerate CO2 absorption and promote crystal growth. NaHCO3 crystal slurry is taken out from the bottom of the tower.

The crystal slurry taken out flows into the thickener automatically by its own pressure.

In the thickener, the clear liquid overflows into the mother liquor bucket, and the thick crystal slurry is separated in a centrifuge, washed with condensate, and the filter cake is sent to dry.

The separated mother liquor enters the mother liquor barrel, and returns to the front with the overflow mother liquor for the preparation of lye.

The baking soda filter cake enters the drying equipment through the electromagnetic vibrating feeder and the screw feeder.

Then it is quickly dehydrated in the drying tube to obtain sodium bicarbonate powder.

There are many factors affect changes in the price of chemicals, which make the price unstable. First, the price change of sodium bicarbonate powder is closely related to the price of of its raw material, soda ash. The rise in the price of soda ash will cause the baking soda price to rise. Second, due to the influence of market supply and demand, the off-season price is relatively low. If the supply of baking soda in the market exceeds the demand, the price will become higher. Third, it will also be affected by some other factors such as freight. So if you have any need, please feel free to contact us for the latest and best sodium bicarbonate powder price.

- Email: sales@chemategroup.com

- Tel: 0086-371-60921621

- Whatsapp: +86 18624832876

- Wechat: +86 18624832876

- ADD: NO.80 PUHUI ROAD,ZHENGZHOU CITY, HENAN PROVINCE, CHINA