Maximize Savings: Purchase MLLDPE in Bulk from Chemate

We’re leading supplier and exporter of plastic raw materials from China for more than twenty years, we focus on world popular brands and also China origin polymers, such as Prime, ExxonMobil, DOW, etc. For the products list and MLLDPE price trends, please feel free to contact us.

Choose The MLLDPE manufacturers

Exxon Exceed™ MLLDPE

Complete models & Competitive price

Prime Evolue™ MLLDPE

Complete models & Competitive price

DOW Dowlex™ MLLDPE

Complete models & Competitive price

DOW ELITE™ EPE

Complete models & Competitive price

What Are Main Applications of Metallocene PE

Food packaging. Metallocene polyethylene has a wide range of applications in the field of food packaging.

Mlldpe film has excellent toughness and strength, and can be thinned, thereby reducing raw materials, processing and transportation costs.

In addition, metallocene polyethylene film is compounded with films such as BOPET, BOPP, and BOPA to make retort packaging bags, narrow packaging bags, etc., which are particularly suitable for packaging meat products, convenience foods, frozen foods and other products.

Its low-temperature sealing performance is excellent, which can increase the production speed of automatic packaging machines and is suitable for high-speed bag production lines.

Production of various films

Metallocene polyethylene has a wide range of applications in the production of various films. These films include agricultural films, which are used for agricultural covering and crop protection.

Laminated films are usually used for packaging and insulation. Heat shrink films are often used for commodity packaging and labeling. These films not only have excellent mechanical properties and durability, but also have specific application advantages due to their special chemical structure.

For example, agricultural films can effectively regulate soil temperature and humidity, laminated films have good insulation properties, and heat shrink films can tightly wrap commodities after heating to provide additional protection.

Application in Medical Fields

Metallocene polyethylene has specific applications in the medical field. This material is used to manufacture medical devices and drug carriers due to its unique chemical and physical properties.

For example, it can be used to manufacture implantable medical devices such as artificial joints or heart stents because of its good biocompatibility, which can reduce the body’s rejection of implants.

In addition, metallocene polyethylene can also be used as a controlled release carrier for drugs, helping drugs reach the target site more effectively, thereby improving the therapeutic effect.

Applications in Rotational molding

Rotomolding is an important use of metallocene polyethylene. Rotomolding is a plastic processing method in which plastic powder is heated and evenly distributed on a mold, and then cooled and solidified to form a product of the desired shape. Metallocene polyethylene is particularly suitable for rotational molding due to its excellent processing properties and mechanical strength. This method can produce products with complex shapes and high-quality surfaces, and is widely used in storage tanks, containers, furniture and many other products.

Used in Automotive accessories

Metallocene polyethylene has a wide range of applications in the field of automotive accessories. This material is widely used in the manufacture of automotive parts due to its excellent chemical resistance, impact resistance and mechanical strength.

For example, it can be used to manufacture automotive bumpers, body shells and interior trims. In addition, metallocene polyethylene also has excellent processing properties and can be easily compounded with other materials, further broadening its application range in automotive accessories.

In general, metallocene polyethylene has become an ideal material for manufacturing automotive accessories due to its superior comprehensive performance.

Use in Wire and cable sheath

Wire and cable sheath is an important component of wire and cable, used to protect the internal structure of the cable and prevent damage to it by external factors such as moisture and mechanical damage. Metallocene polyethylene (mPE) is a high-performance polyethylene material and is widely used in wire and cable sheath. Its advantages are good anti-aging performance, UV resistance and chemical corrosion resistance, which can effectively protect the internal structure of the cable and extend the service life of the cable. Therefore, the application of metallocene polyethylene in wire and cable sheath has high practical value and economic benefits.

How does metallocene polyethylene perform?

Better transparency and lower haze value. The transparency of polyethylene polymers decreases with increasing crystallinity. When the crystallinity is constant, its transparency increases with increasing molecular weight. Therefore, at the same density, MLLDPE has better transparency and lower haze value than traditional polyethylene.

Better tensile and impact strength. The modulus and yield stress of polyethylene polymers are usually closely related to their crystallinity. Therefore, traditional PE and metallocene polyethylene with similar density generally have similar modulus and yield stress. However, the tensile strength of the two is quite different. Compared with traditional polyethylene, metallocene PE has a larger elongation at break. Impact strength depends on the molecular structure and molecular weight of polyethylene polymers. Since MPE has a larger molecular weight and denser distribution than traditional polyethylene, it has better impact strength.

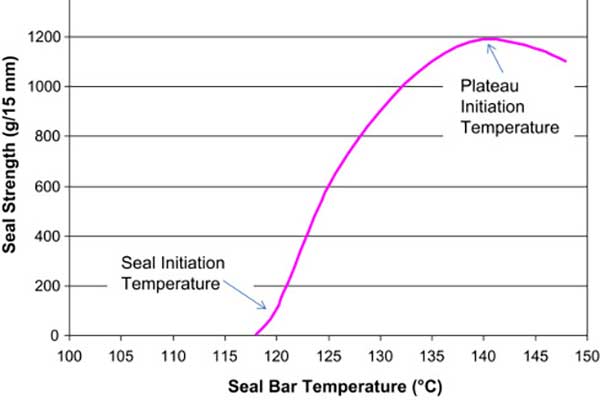

Lower heat sealing temperature and higher heat sealing strength. The melting point of polyethylene polymers is mainly determined by the high molecular weight part with less comonomer. Since traditional polyethylene has a wide molecular weight distribution structure, its melting point is higher than that of metallocene polyethylene at the same density. Therefore, metallocene polyethylene has a lower heat sealing temperature and higher heat sealing strength than traditional polyethylene.

- Email: sales@chemategroup.com

- Tel: 0086-371-60921621

- Whatsapp: +86 18624832876

- Wechat: +86 18624832876

- ADD: NO.80 PUHUI ROAD,ZHENGZHOU CITY, HENAN PROVINCE, CHINA